Noise at Work Assessment

Factory Employee Noise Exposure

Noise At Work Assessment | Employee Noise Exposure

SUMMARY

This report documents noise levels taken during an assessment of operative’s noise exposure. It was carried out at a representative site. It includes recommendations of actions to be carried out to ensure that staff comply with the requirements of “The Control of noise at work regulations 2005 “which became applicable in April 2006.

Objectives

To carry out an assessment of Engineers noise exposure in accordance with “The Control of Noise at Work Regulations 2005”, which came into force April 2006.

RECCOMENDATIONS

In order to comply with The Control of Noise at Work regulations 2005 it is recommended that the following actions be undertaken.

Regulation 5 - Assessment of the risk to health and safety created by exposure to noise in the workplace:

This report records the measurements taken as part of this noise assessment. The assessment should be reviewed and updated under the following conditions

a. Changes in the work place such as alterations to the building,

b. Changes in people such as new staff or changes to shift roster,

c. New plant or machinery,

d. After a period of two years has passed with no other changes.

It should be noted that as plant ages its noise level may rise. It is recommended that assessments are kept for a period of 40 years. If the company ceases to trade, then the reports must be passed to the enforcing authority.

Regulation 6 - Elimination or control of exposure to noise in the workplace:

Site should ensure that the risk from exposure to noise for their employees is either eliminated at source or where this is not reasonable practicable, then it is reduced to as low a level as is reasonably practicable. Due to the nature of the plant used it is not possible to reduce any further the noise levels engineers will be exposed to.

Regulation 7 – Hearing Protection

Personal hearing protection should only be used as a last resort when all possible noise reduction measures have been achieved under regulation 6.

For employees who are likely to be exposed to LEP,d at or above the Lower Action Value (LAV) of 80dB(A) but below the Higher Action Value (HAV) 85dB(A) suitable hearing protection must be made available , however the wearing of such protection is optional but advisable.

For areas where the employees LEP,d has been identified as exceeding the UAV of 85dB(A) then the wearing of suitable Hearing protection is compulsory. These areas shall also be marked as Hearing Protection Zones and marked as with appropriate signage. The signs used shall comply with the Health & Safety (Safety Signs and Signals) Regulations 1996.

The regulations also have an Exposure Limit value (ELV) of 87 dB (A) this value to be calculated taking into account personal hearing protection worn by operatives. Guidance issued by the HSE states that under real use hearing protectors would give lower protection than predicted by the manufacturer. This can be caused by the wearing of spectacles, incorrect selection of protection or poor fitting of protection.

To take these factors into account the HSE recommend that the protector is de-rated by 4dB.

Regulation 8 – Maintenance and use of equipment

Site shall ensure that all equipment under their control on site (e.g. exhaust silencers, shrouds and acoustic enclosures) are in accordance with these Regulations, fully maintained and kept in good repair in accordance with manufacturer’s instructions.

Employees shall use as instructed any and all hearing protection as issued by the company, they shall keep it clean and in good condition and stored in a clean dry location. Also all defects are to be immediately reported to the site Supervisor so that the protection can be replaced.

Regulation 9 - Health Surveillance

Site should provide health surveillance to engineers regularly exposed to noise levels above the UAV of 85dB (A). For engineers exposed to noise levels between the LAV and UAV, or for occasional exposure above the UAV, health surveillance will only be required if information comes to light that the engineer may be particularly sensitive to noise-induced hearing loss (NIHL).

Regulation 10 - Information, Instruction and Training

Cherwell Valley Silos will provide to each of their employees who are liable to be exposed to a LEP,d equal to or above the LAV Instruction, information and training of the following subjects:

(a) The nature of risks from exposure to noise,

(b) The organisational and technical measures taken in order to comply with the requirements of Regulation 6,

(c) The exposure limit values and upper and lower exposure levels set out in Regulation 4,

(d) The significant findings of the risk assessment, including any measures taken with an explanation of those findings,

(e) The availability and provision of personal hearing protection under Regulation 7 and the correct use in accordance with Regulation 8(2),

(f) Why and how to detect and report signs of hearing damage,

(g) The entitlement to health surveillance under Regulation 9 and its purposes,

(h) Safe working practices to minimise exposure to noise,

(i) The collective results of any health surveillance undertaken in accordance with regulation 9, in a form designed to prevent those results being identified as relating to a particular person.

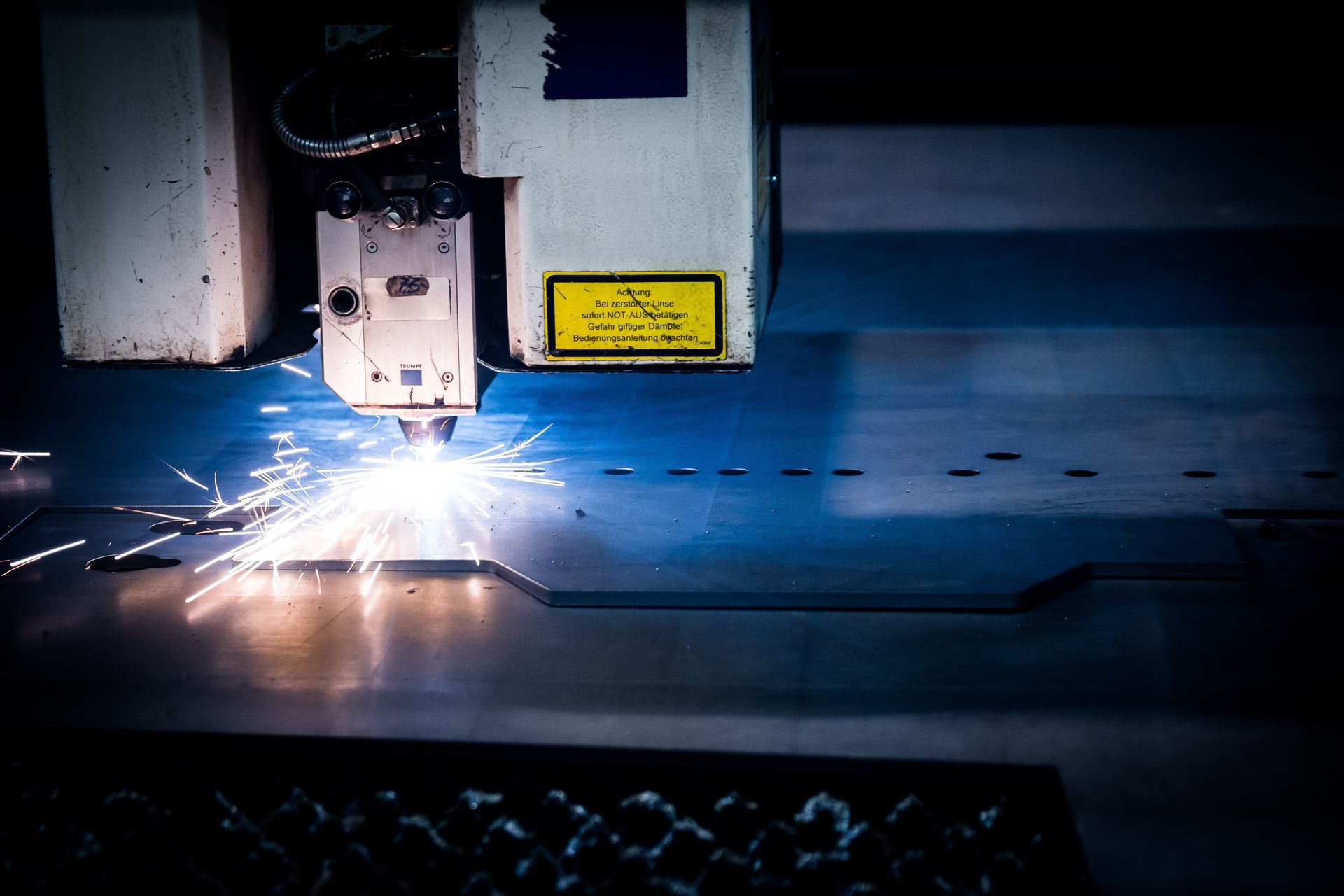

NOISE ASSESSMENT

An assessment of the noise exposure for Site staff within the various areas’ was carried out using a Cirrus Advanced Type 1 Sound Level Meter. Confirmation of calibration was conducted using a calibrator at 94dB, 1 KHz tone, both before and after testing. Copies of the company calibration certificates can be provided upon request.

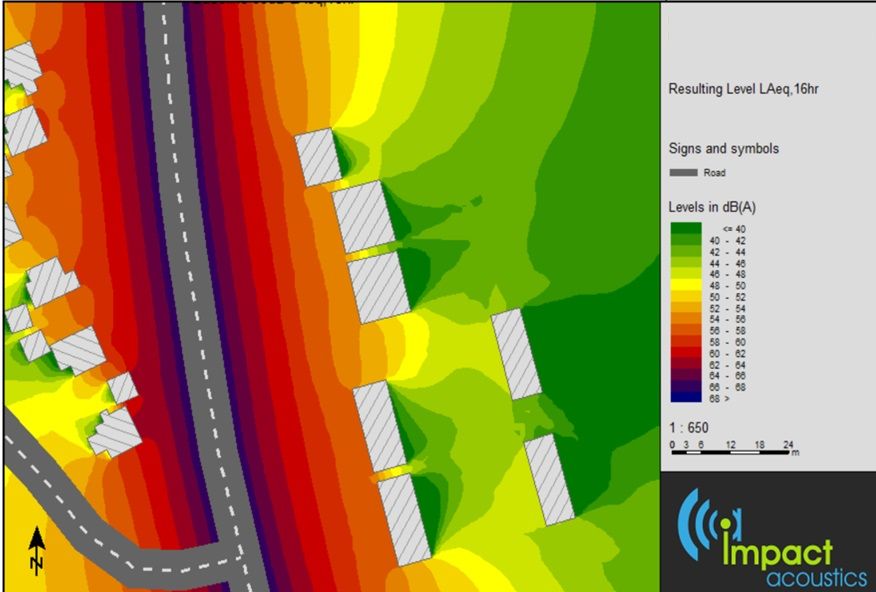

Measurements were taken of “A” weighted sound pressure levels (LAeq) at the assumed operative’s ear position throughout the site.

It was decided to carry out a single assessment to cover staff working on site and shows the areas within the site with the highest levels of exposure.

Methodology

The survey was carried out using the following methods:

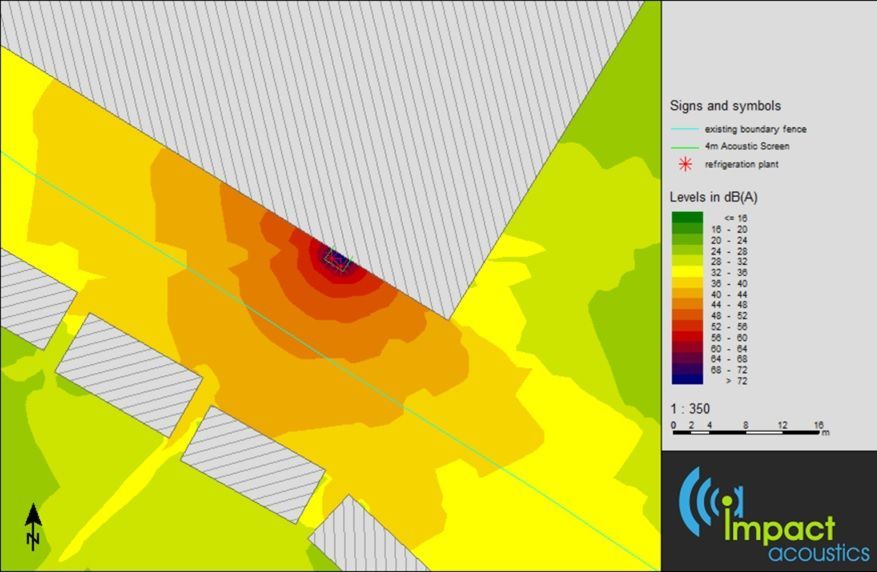

• Each zone of concern was assessed individually for in order to assign noise hazard areas (see Table 1)

3.1.1 Measurements

All spot noise measurements were carried out using a Class I integrating sound level meter. The meter was calibrated on site prior to and after the measurements being taken. Measurements of the value of equivalent continuous sound level (Leq) over sample periods from which LEP,d is calculated were taken. The C weighted Peak noise levels were also measured to ensure that the Peak of 140dB(C) was not exceeded.

General area noise levels at the site were made by holding the sound level meter at approximately 1.5m above ground and taking sample sound level measurement integrating over a representative period.